Features

Features

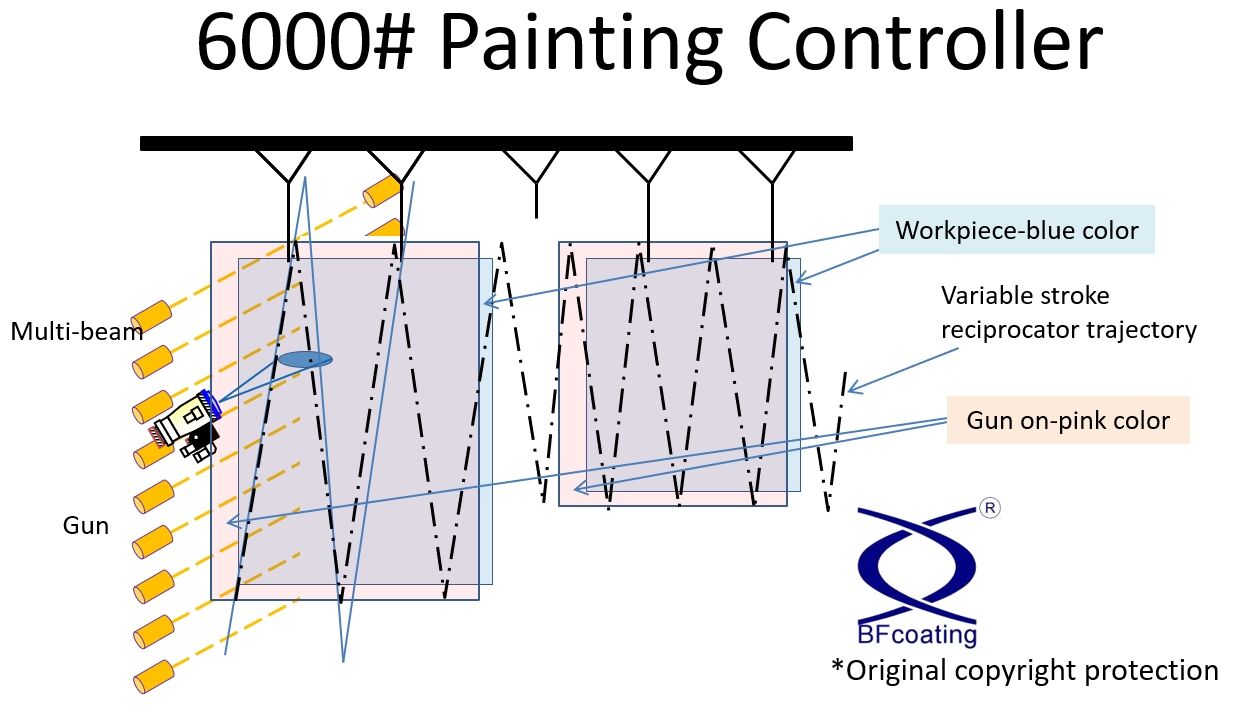

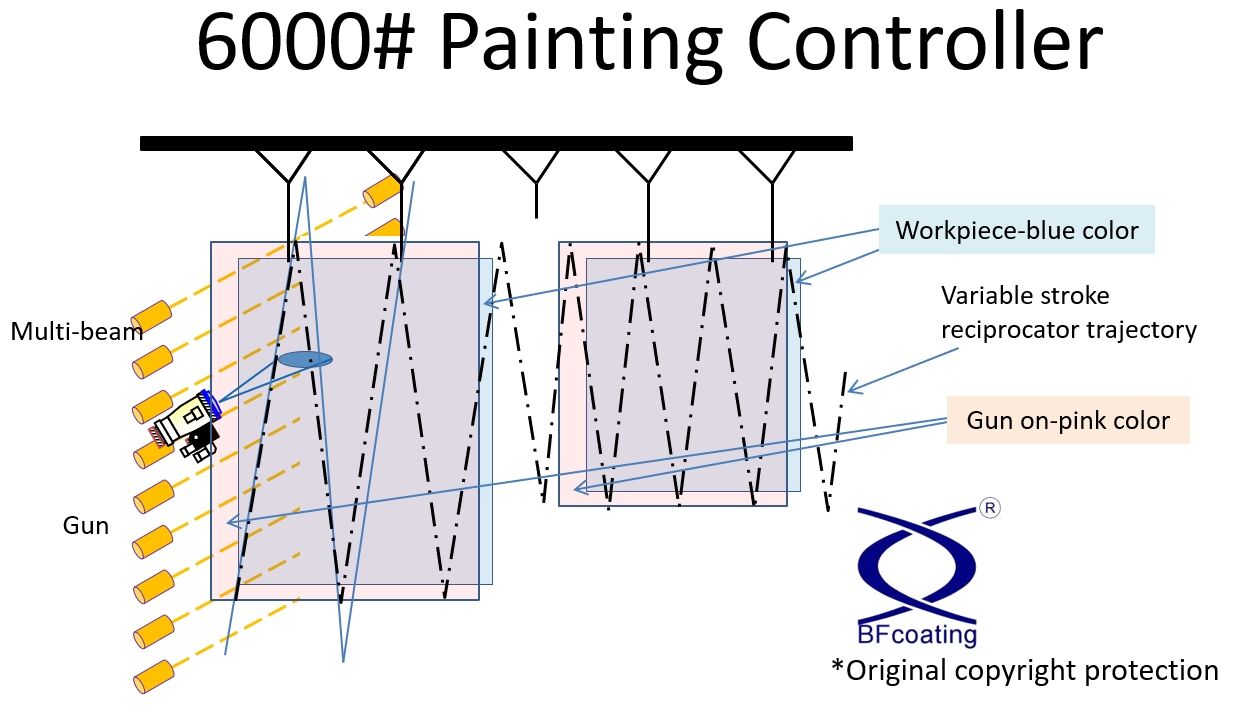

1. The stroke and position of the reciprocator change automatically according to the height of the workpiece, increasing the spraying efficiency and production capacity.

2. The second dimension uses full-light curtain workpiece detection, which requires high investment costs.

3. In the direction of the conveyor and the up and down direction, the spray gun automatically turns ON/OFF in two dimensions. If there is no workpiece or hollow object in front of the spray gun, it will not trigger on, saving the waste of paint.

4. With the reciprocator spraying, the light curtain detect the workpiece, and with the computer's two-dimensional optimal parameter setting , the spray gun automatically turns ON/OFF for spraying, saving paint.

5. The two-dimensional increase and decrease spraying can be individually set to match the shape of the workpiece for optimal spraying operations.

6. Easy to install, the resolution of the first dimension can be measured in distance. The height of the second dimension use a set of integrated light curtains, which is easy to install.

7. Compared to old-style photographic systems, the level of maintenance personnel does not need to be very high, and there is almost no service demand for general industrial PLC and full-light curtain systems.

8. Use industrial-grade PLC to reduce interference and malfunction.

Specification

Specification

| 6000#: A21. x-y axis two-dimensional control: the stroke automatically changes with the workpiece | ||

| A21 Light curtain computer controller specification | ||

| 1 | spray parameter | Able to freely adjust in HMI or panel |

| 2 | More memory signal | One station can satisfy the requirement of one reciprocator or one booth. |

| 3 | No. of spray guns can be controlled independently | One station 4pcs, 6 station 24pcs. |

| 4 | Increase and reduce spray | Front edge、rear edge、upper edge、lower edge |

| 5 | The quantity of reciprocator can be control at the same time | 1~6 sets |

| 6 | Reciprocator spray up and down setting | PLC self-calculating spraying |

| 7 | HMI | Conveyor running speed instructions |

| 8 | HMI | Light curtain detection status display |

| 9 | Conveyor signal | Input from external encoder |

| 10 | Interlock | When the conveyor belt stops, spraying automatically stops. If it runs again, spraying will resume immediately. |

| 11 | Detect workpiece | Use 2cm or 3cm resolution light curtain |

| 12 | The hanging area will automatically not spray | If there is no workpiece in the effective spraying area of the reciprocator, it will automatically return to the origin and standby. |

| 13 | HMI | 10" Color |

Components selection:

Use famous brands components, which have the characteristics of reliability and long life.

For example:

PLC use Japan OMLON, HMI use Taiwan Weintek, Light curtain use Germany SICK.