Advantages

Advantages- Improve surface quality

Immediate spray upon mixing, fixed viscosity, and excellent atomization effect.

- Labor saving and reduced work

No need for additional work like measuring and mixing.

- Reduce waste、lower cost

Compared to pre-mixing, only the required amount is mixed, significantly reducing waste paint

- Environmental Protection

Reduced solvent usage in pipes, simplified and shortened cleaning of paint pipes, and a significant reduction in cleaning solvents.

- Improve Quality

Computer monitors the pressure at the inlet and outlet of the main agent and hardener; poor cleaning and mixing can be avoided.

- ISO9000 Compliance

Capable of managing paint usage and other factors according to ISO9000 production management reporting requirements.

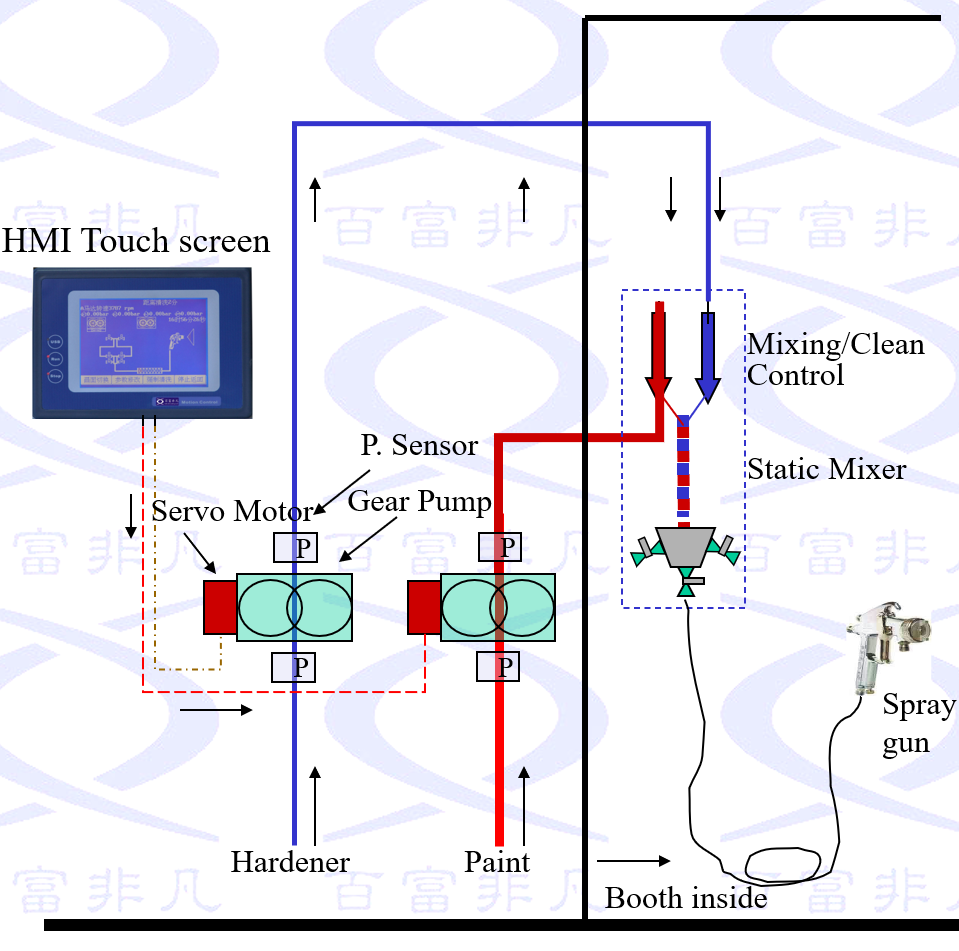

GearMix working principle

GearMix working principle

The computer automatically calculates the required rotational speed for the continuous flow of A and B based on the discharge volume and mixing ratio requirements. It drives the gears with a servo motor to achieve the desired stable discharge rate.

Comparison of GearMix with other 2K system

Comparison of GearMix with other 2K system

| Topic | Gear pump | Flow meter |

| Discharge value setting | cc/Min | Without (high-end models have this feature.) |

| Mix and discharge accuracy | The model selection based on flow rate, max. up to ±0.5%. | max. up to ±1%. |

| Applicable viscosity Ford 4# | Min. 10 second | Max. 20 second, poor mixing accuracy、unstable output |

| Suitable paint flow range | Based on gear pump 9cc~3000cc | Max. 100cc ,poor mixing accuracy、unstable output |

| Low flow rate, high mixing ratio | Able | The min. flow rate for the hardener is 10 cc/min, and ratios exceed10:1 is unstable. |

| Operability | Easy to install and use, with few variables | The pressure comes from an external pump, with many variables due to the length and design of the pipe |

| Stable discharge and mixing ratio | The volumetric output of the autonomous gear pump is not significantly affected by pressure, temperature, or viscosity. | External pump pressure influences stability, and the pulse from trigger on/off the spray gun, as well as the response time of the dead circulation system, are affected by factors like temperature and viscosity. |

| Instant pressure | Instantaneous pressure is achieved when the spray gun trigger is on/off, allowing robots to spray with immediate pressure, which shortens the trajectory and saves paint and time. | Factors such as external pump pressure, pipeline design, and friction in the piping can lead to slower responses, longer robot trajectories, and reduced paint efficiency and productivity. |

| Continuous mixing | Two gear pumps operate continuously for consistent mixing, ensuring more uniformity and reliable physical and chemical properties | The main agent and hardener are supplied alternately and intermittently, resulting in segmented mixing and poor uniformity.. |

| Coating film tolerance range | Suitable for applications with a small range and high requirements for physical and chemical properties. | Suitable for applications with a large range and high requirements for physical and chemical properties. |

| Instant cleaning solvent time | No pre-mixing design, resulting in lower usage and shorter processing time. | Pre-mixing design requires a large amount of solvent, often leading to incomplete cleaning, particle generation, and frequent disassembly for cleaning that takes over 1.5 hours. |

| Compatibility with EST spray gun and robot | Compact size with full insulation material | Larger size with all-metal materials |

| Cost | Servo motor control and gear pump explosion-proof technology have higher costs. | The combination of flow meter and valve offers lower costs. |

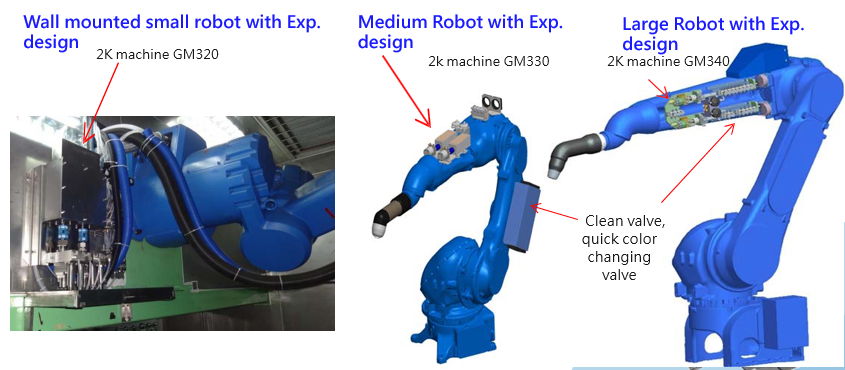

GearMix model selection table

GearMix model selection table

| Model | Flow rate cc/min. | Mixing ration range | A pump cc/rev. | B pump cc/rev. | Application |

| GM-XXX-30 | 3~30 | 100:5~100:100 | 1.2 | 0.3 | Mobile phone、digital camera |

| GM-XXX-50 | 5 ~ 50 | 100:5~100:100 | 1.8 | 0.6 | Mobile phone、digital camera |

| GM-XXX-100 | 10 ~ 100 | 100:8~100:100 | 1.8 | 1.8 | Mobile phone、digital camera、NB |

| GM-XXX-200 | 20 ~ 200 | 100:7~100:100 | 3 | 3 | NB、LCD、car interior parts |

| GM-XXX-400 | 50 ~ 400 | 100:4~100:100 | 6 | 3 | Bumper、Furniture |

| GM-XXX-800 | 100 ~ 800 | 100:4~100:100 | 6 | 3 | Car body、car underbody、Furniture |

| GM-XXX-1000 | 200 ~1000 | 100:3~100:100 | 6 | 6 | Furniture |

*The mixing ratio will affect the discharge amount; please confirm the mixing ratio and discharge amount requirements with us in advance