This VOCs Treatment Technology Selection Decision Guide will follow the core logic of 'Clarify Requirements → Analyze Factors → Match Technologies → Validate and Adjust' to help you quickly implement project selection and avoid rework of solutions caused by incomplete consideration.

A. Clarify Project Basic Requirements (Selection Premise)

First, lock in the project's 'hard indicators', which are the core basis for subsequent selection and indispensable.

1. Clarify Purification Efficiency Requirements: Based on environmental protection standards in the project location (e.g., 'Volatile Organic Compound Emission Standards'), determine the required VOCs removal rate (e.g., ≥95%, ≥99%).

2. Determine Wastewater Treatment Volume: Calculate the total volume of waste gas generated during production (unit: m³/h), which directly determines the equipment specifications and size.

3. Confirm Environmental Compliance Requirements: Clearly specify whether monitoring of secondary pollutants such as NOx and dioxins is required to avoid issues of secondary pollution exceeding standards after selection.

B. Analyze Core Influencing Factors (Key Decision Points)

Analyze around the three core factors of 'Waste Gas Characteristics, Site Conditions, Economic Cost', each of which directly affects technology adaptability.

1. Waste Gas Characteristics Analysis (Most Critical Factor)

• Waste Gas Concentration:

◦ Low concentration (<500mg/m³): Prioritize RCO (low-temperature combustion is more energy-efficient); if the concentration is too low (<100mg/m³), it needs to be paired with a concentration device before using RCO/RTO.

◦ Medium concentration (500-10000mg/m³): Both RCO and RTO are applicable, further screening is needed based on other factors.

◦ High concentration (>10000mg/m³): Prioritize RTO (high-temperature combustion is more thorough, and high-concentration waste gas can self-supply energy, reducing energy consumption).

• Waste Gas Composition:

◦ Single component (e.g., only benzene, toluene): Both RCO and RTO are applicable, with RCO being more energy-efficient.

◦ Contains dust, sulfides, halogens, etc.: If selecting RCO, a pre-treatment device (e.g., dust removal, desulfurization tower) must be added first to avoid catalyst poisoning; if the impurity content is high, directly select RTO (no catalyst, no need to worry about poisoning).

◦ Contains high-boiling-point, easily polymerizable substances: Prioritize RTO (high temperature can thoroughly decompose; RCO low temperature may cause substances to adhere to the catalyst surface, affecting efficiency).

• Waste Gas Temperature and Humidity:

◦ High humidity (>80%): Dehydration treatment must be done first before entering RCO/RTO to avoid affecting the performance of heat storage bodies or catalysts.

2. Site Conditions Analysis

• Floor Area: For small sites (e.g., workshop renovation), prioritize RCO (equipment volume is 30%-50% smaller than RTO); for sufficient area, consider RTO.

• Height Limitations: RTO has a tall heat storage chamber; if the site height <5m, it is recommended to select RCO or horizontal RTO (requires custom ordering).

• Surrounding Environment: If there are residential areas nearby, prioritize RCO (operating temperature is low, no high-temperature safety hazards, and lower noise).

3. Economic Cost Analysis

• Initial Investment: If budget is limited and waste gas concentration is stable, TNV can be selected; if budget is充足 and long-term benefits are pursued, select RCO/RTO.

• Long-term Operation and Maintenance:

◦ Few operation and maintenance personnel, hoping to reduce maintenance workload: Select RTO (no catalyst, only regular cleaning of heat storage bodies is needed).

◦ Acceptable for regular replacement of consumables: Select RCO (catalyst life is about 2-3 years, requiring regular replacement, but energy consumption cost is lower than TNV).

◦ Energy-sensitive projects: Prioritize RCO/RTO (high heat storage efficiency); avoid selecting TNV (energy consumption is 2-3 times that of RCO).

C. Technology Matching and Preliminary Selection (Direct Correspondence to Solutions)

Based on the above factors, the following preliminary selection conclusions can be directly corresponded:

| Scenario Combination | Recommended Technology | Remarks (Precautions) |

|---|---|---|

| Low concentration + Small site + No impurities + High energy-saving requirements | RCO (Regenerative Catalytic Oxidation) | It is necessary to confirm that the waste gas components do not contain catalyst-poisoning substances. |

| Medium-high concentration + High purification efficiency (≥99%) + Large site | RTO (Regenerative Thermal Oxidation) | If there are residential areas nearby, an NOₓ treatment device must be installed. |

| High concentration + Limited budget + Temporary transition project | TNV (Thermal Nitrogen Oxide) | Only suitable for short-term use; long-term energy consumption cost is high. |

| Low concentration + With impurities + High purification efficiency | Concentration device + RTO | Concentrate the waste gas first, then send it to RTO for combustion, balancing energy saving and purification efficiency. |

D. Feasibility Verification and Adjustment (Final Confirmation)

After preliminary technology selection, three verifications are required to ensure the feasible implementation of the scheme:

- Waste Gas Pretreatment Verification: If RCO is selected, confirm whether the pretreatment devices (such as dust removal and desulfurization equipment) can meet the impurity requirements at the catalyst inlet (e.g., dust content <10mg/m³).

- Equipment Installation Verification: Confirm whether the site can accommodate the equipment and supporting pipelines (e.g., the regenerator height of RTO, the catalyst replacement space of RCO).

- Cost Payback Period Verification: Calculate the break-even period between the initial investment of RCO/RTO and energy consumption savings. Generally, the payback period of RCO/RTO is 1-3 years. If it exceeds the project expectation, the selection needs to be readjusted.

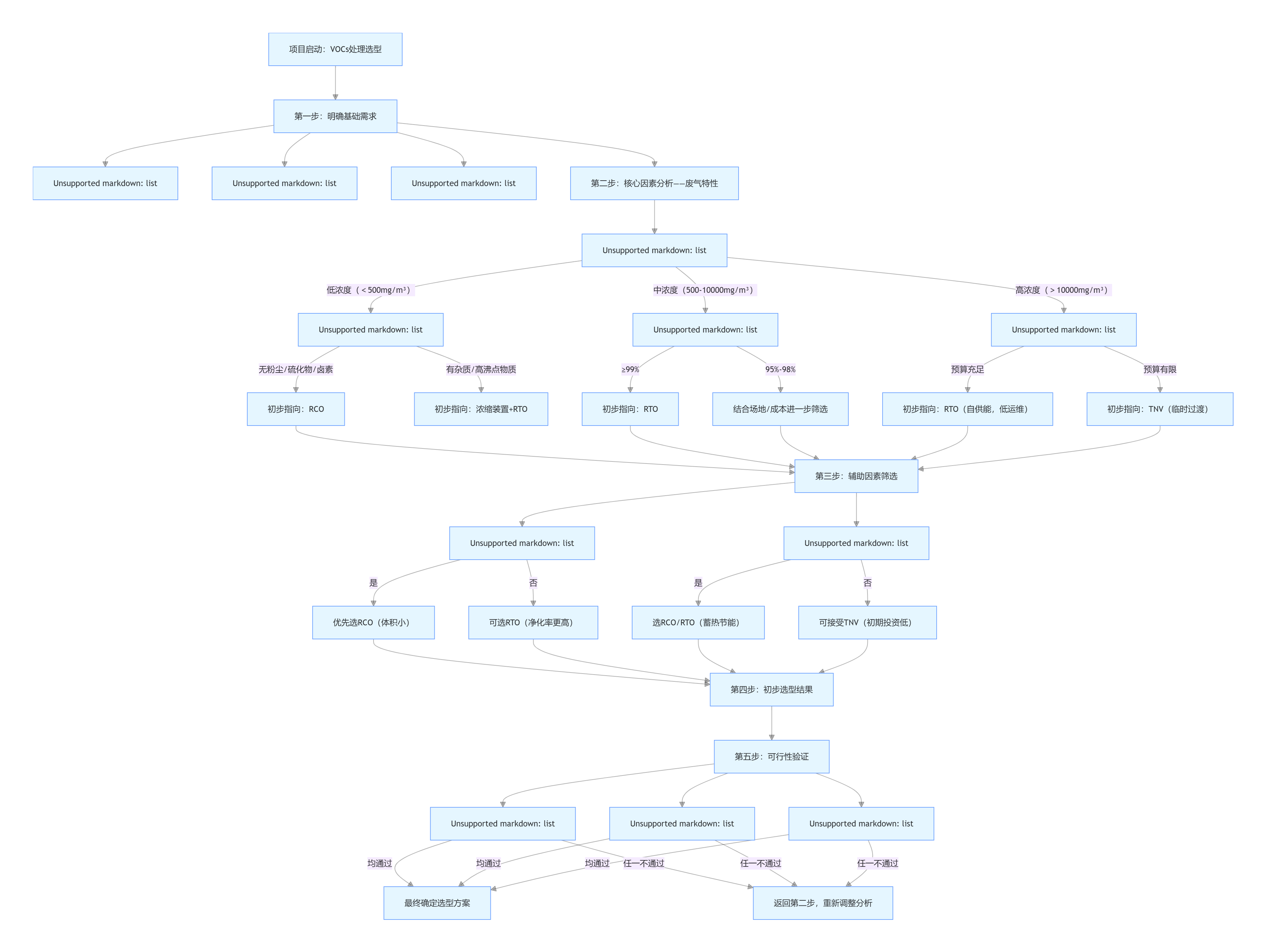

Flowchart Usage Instructions

1. Logic of Use: Proceed from left to right step by step. At each judgment node (such as 'Exhaust Gas Concentration Judgment' and 'Budget Judgment'), select the branch based on the actual project situation, which will ultimately lead to an initial selection result.

2. Key Nodes: ◦ Red bold nodes (such as 'Exhaust Gas Characteristic Analysis' and 'Feasibility Verification') are core to the selection process and require key data confirmation. ◦ If the verification phase is not passed, return to 'Exhaust Gas Characteristic Analysis' for readjustment to avoid directly modifying the selection result, which could lead to subsequent risks.

3. Applicable Scenarios: Can be directly screenshot and inserted into the solution PPT, or printed for on-site discussions to help quickly align the selection logic.