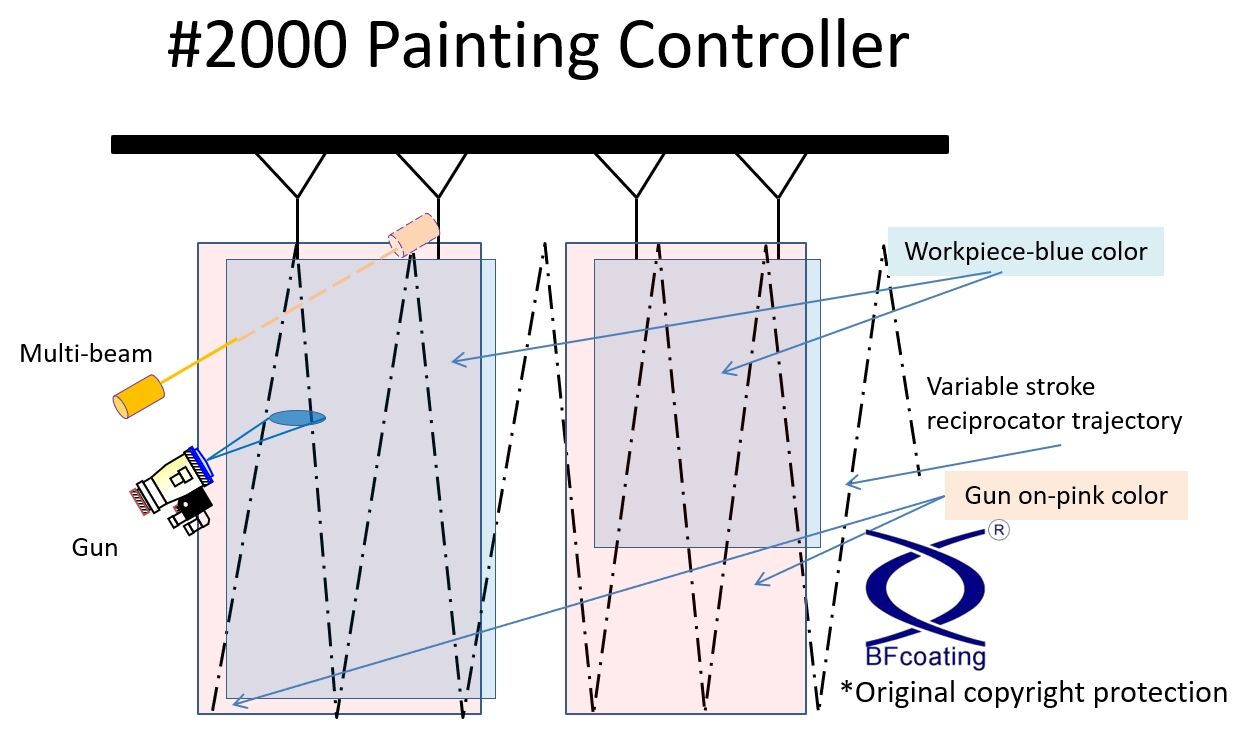

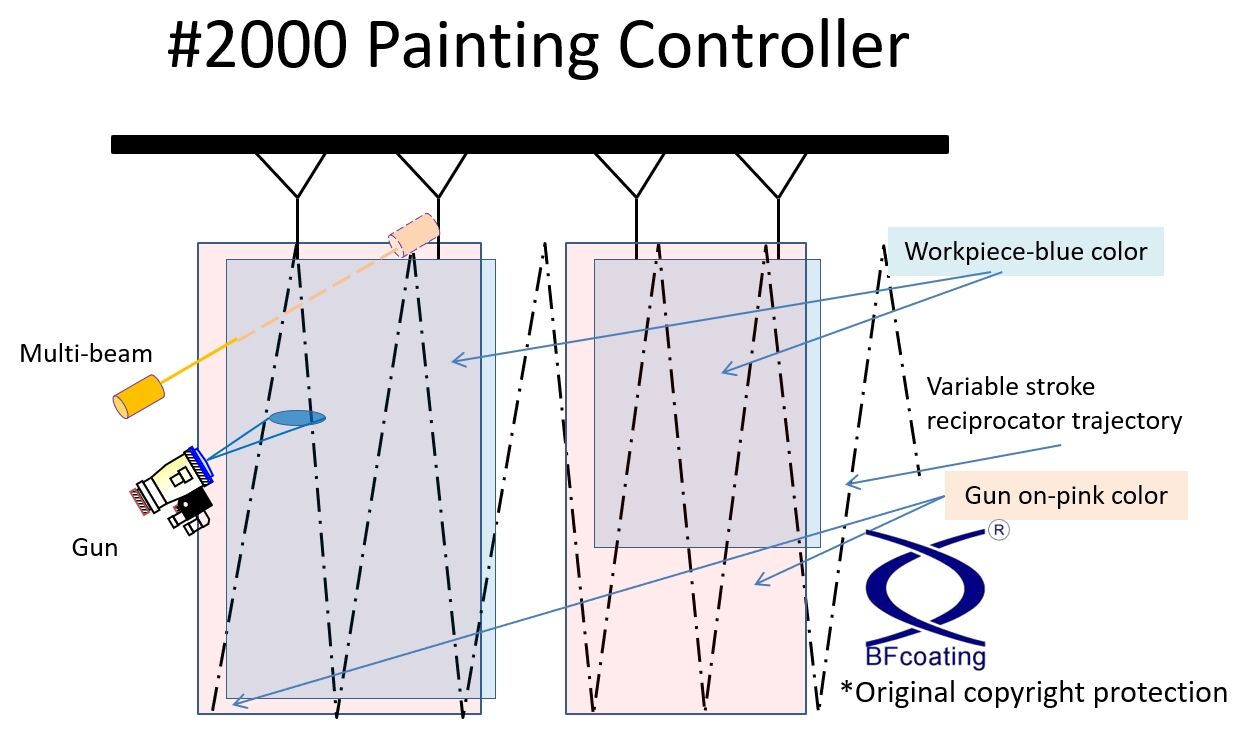

2000# Side spray Optical beam control

No.

2000#

Intro.

Energy-saving controller - Conveyor direction one dimension spray gun automatically on/off 2000# Type

Features

Features

- Using a variable stroke reciprocator, the reciprocating point of the reciprocator can be set by the HMI to set its reciprocating position and stroke according to the height of the workpiece, which can improve the output.

- Optical eyes or gratings to detect workpiece, with low investment and maintenance costs.

- In the direction of the conveyor, the spray gun is automatically on/off in one dimension. Spray gun triggers off when no workpiece that saving the waste of paint.

- With the reciprocator, the optical eyes or grating can detect the position of the workpiece, and then do one-dimensional control spraying.

- One-dimensional reciprocating speed can be set for more and less spray.

- Easy to install, the one-dimensional resolution is synchronized with the encoder to achieve accurate spraying.

| 2000# : A11. x-axis length direction control, spray gun ON/OFFautomatically | ||

| A11 Touch panel controller specification | ||

| 1 | Touch panel | 7" HMI |

| 2 | Max. memory signals | Available for two spray booths |

| 3 | No. of spray guns can be controlled independently | 4 pcs(Max. expand to 16) |

| 4 | Increase and reduce spray | 0~±999 |

| 5 | The No.of reciprocator can be controlled at the same time | 1 set to 4 set |

| 6 | Reciprocator spray up and down setting | Non |

| 7 | Conveyor running instructions | Conveyor running instructions |

| 8 | Workpiece detection indication | Workpiece detection indication |

| 9 | Conveyor signal | Input from an external encoder |

| 10 | Interlock | Conveyor stops, the spraying stops automatically. And when it runs again, the spraying resumes immediately. |

| 11 | The No. of optical eyes to detect workpiece. | 1 pce |

| 2100# : A14.x-axis length direction control - 4 sections,spray gun ON/OFFautomatically | ||

| A14 Touch panel controller specification | ||

| 1 | Touch panel | 7" HMI |

| 2 | Max. memory signals | Available for two spray booths |

| 3 | No. of spray guns can be controlled independently | 4 pcs(Max. expand to 16) |

| 4 | Increase and reduce spray | 0~±999 |

| 5 | The No.of reciprocator can be controlled at the same time | 1 set to 4 set |

| 6 | Reciprocator spray up and down setting | Non |

| 7 | LED No.1 | Conveyor running instructions |

| 8 | LED No.2 | Workpiece detection indication |

| 9 | Conveyor signal | Input from an external encoder |

| 10 | Interlock | Conveyor stops, the spraying stops automatically. And when it runs again, the spraying resumes immediately. |

| 11 | The No. of optical eyes to detect workpiece. | X-1 pce / Y- 4 pcs |

Components selection:

Use famous brands components, which have the characteristics of reliability and long life.

For example:

Japan Omron PLC, Taiwan Weitek HMI, Germany Sick Optical eyes.