Feature

Feature

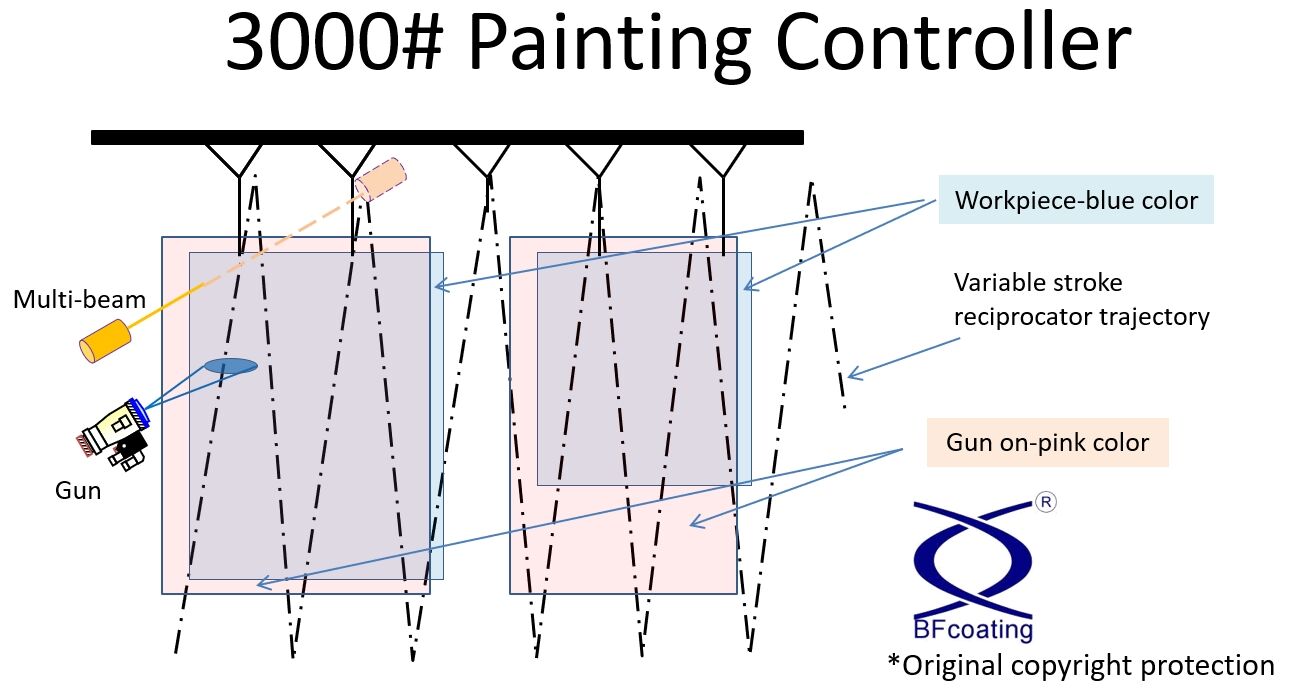

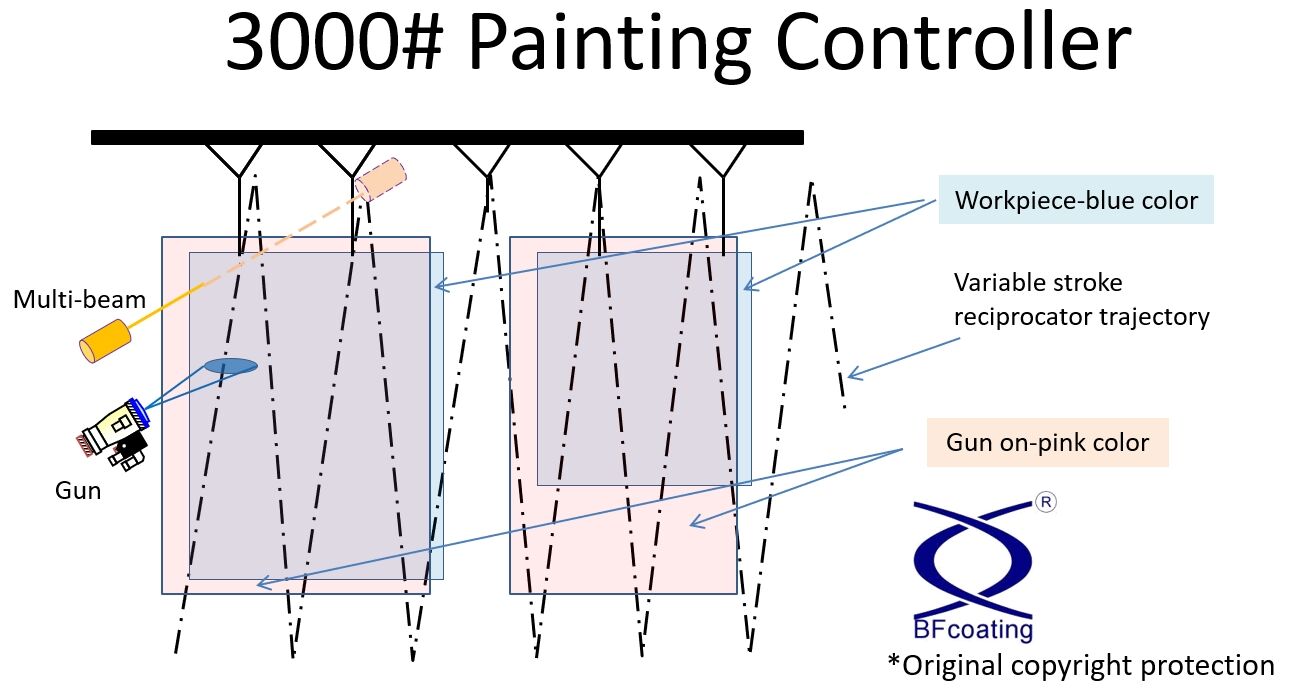

1. The reverse point of the reciprocator is on the outside of the workpiece to avoid thick coating and poor sagging caused by the turning point.

2. The workpiece is detected by the optical eye, and the cost of investment and maintenance are lower than control of the light curtain.

3. In the direction of the conveyor, the spray gun is automatically on/off in one dimension. Spray gun triggers off when no workpiece that saving the waste of paint.

4. With the reciprocator spraying, only do one-dimensional control spraying when the optical eye detects workpiece. The height of the second dimension adopts the preset spraying area to save paint.

5.One-dimensional speed can be set to increase overcoating and decrease spraying

6.Easy to install, one-dimensional resolution is sensed by encoder, photoelectric switch or signal machine.

| 3000#: A12. X-axis length direction control + Y-axis position setting, automatically spray gun ON/OFF | ||

| A12 Touch panel controller specification | ||

| 1 | Touch panel | 7" Colorful、10" Colorful |

| 2 | Max. memory signals | Available for two spray booths |

| 3 | No. of spray guns can be controlled independently | 4 pcs(Max. expand to 16) |

| 4 | Increase and reduce spray | 0~±999 |

| 5 | The No.of reciprocator can be controlled at the same time | 1 set to 4 set |

| 6 | Reciprocator spray up and down setting | Independent setting of ON/OFF points for up and down travel |

| 7 | LED No.1 | Conveyor running instructions |

| 8 | LED No.2 | Workpiece detection indication |

| 9 | Conveyor signal | With external and built-in signal settings |

| 10 | Interlock | Conveyor stop, spray automatic stop. |

| 11 | The No. of optical eyes to detect workpiece. | According to the shape of the workpiece, the standard is 1, which can be expanded to 4, or the grating can be used instead. |

| 3100#: A13. X-axis length direction control + Y axis position variety according to travel,spray gun ON/OFF automatically | ||

| A13 Touch panel controller specification | ||

| 1 | Touch panel | 7" Colorful、10" Colorful |

| 2 | Max. memory signals | Available for two spray booths |

| 3 | No. of spray guns can be controlled independently | 4 pcs(Max. expand to 16) |

| 4 | Increase and reduce spray | X ±99, Y 4 sections |

| 5 | The No.of reciprocator can be controlled at the same time | 1 set ~ 4 sets |

| 6 | Reciprocator spray up and down setting | Automatically detection by the Y-direction optical eye. |

| 7 | LED No.1 | Conveyor running instructions |

| 8 | LED No.2 | Workpiece detection indication |

| 9 | Conveyor signal | With external and built-in signal settings |

| 10 | Interlock | Conveyor stop,spray automatic stop. |

| 11 | The No. of optical eyes to detect workpiece. | X-1 pce / Y- 4 pcs |

Components selection:

Use famous brands components, which have the characteristics of reliability and long life.

For example:

Japan Omron PLC, Taiwan Weitek HMI, Germany Sick Optical eyes.