Powder recovery booth

Powder recovery booth

Color change time of PVC booth is shortened!

Cleaning time is reduced!

| Down suction large cyclone recovery booth | ||||

| Model | LCB-P | LCB-S | ||

| Main body material | PVC | SUS | ||

| powder supply device | Powder supply tank/powder supply center/addition feeding tank | |||

| Bottom design | Surge Blow/Flip | |||

| Cyclon specification CR | 800 | 1100 | 1300 | 1400 |

| Back Filter Unit BFU | 6—12 | 9—18 | 12—24 | 12—24 |

| Max. air flow rate m3/hr | 10,000 | 14,000 | 20,000 | 24,000 |

*Application: Frequent color change, and more than 4 colors.

LCB Large cyclone recovery booth

LCB Large cyclone recovery booth

| Small cyclone recovery booth | ||||

| Model | MCB-P | MCB-S | ||

| Main body material | PVC | SUS | ||

| powder supply device | Powder supply tank/powder supply center/addition feeding tank | |||

| Bottom design | Surge Blow/Flip | |||

| Cyclon specification CR | 6 | 9 | 12 | 16 |

| Back Filter Unit BFU | 6—12 | 9—18 | 18—24 | 24—32 |

| Max. air flow rate m3/hr | 10,000 | 14,000 | 20,000 | 24,000 |

*Application: Frequent color change, and more than 4 colors.

*Advantages: Applicable when the height of the factory building is limited

MCB Small cyclone recovery booth

MCB Small cyclone recovery booth

| Single stage recovery booth | |||

| Model | FRS-P | FRS-S | |

| Main body material | PVC | SUS | |

| powder supply device | Powder supply tank/powder supply center/addition feeding tank | ||

| Bottom design | Surge Blow/Flip | ||

| Back Filter Unit BFU | 6—12 | 9—18 | 18—24 |

| Max. air flow rate m3/hr | 10,000 | 14,000 | 20,000 |

*Application: Infrequent color change, when changing color, you can add color cartridge and powder tank, and use less than 4 colors.

*Advantages: The cost of investment introduction is low.

FRS Single stage recovery booth

FRS Single stage recovery booth

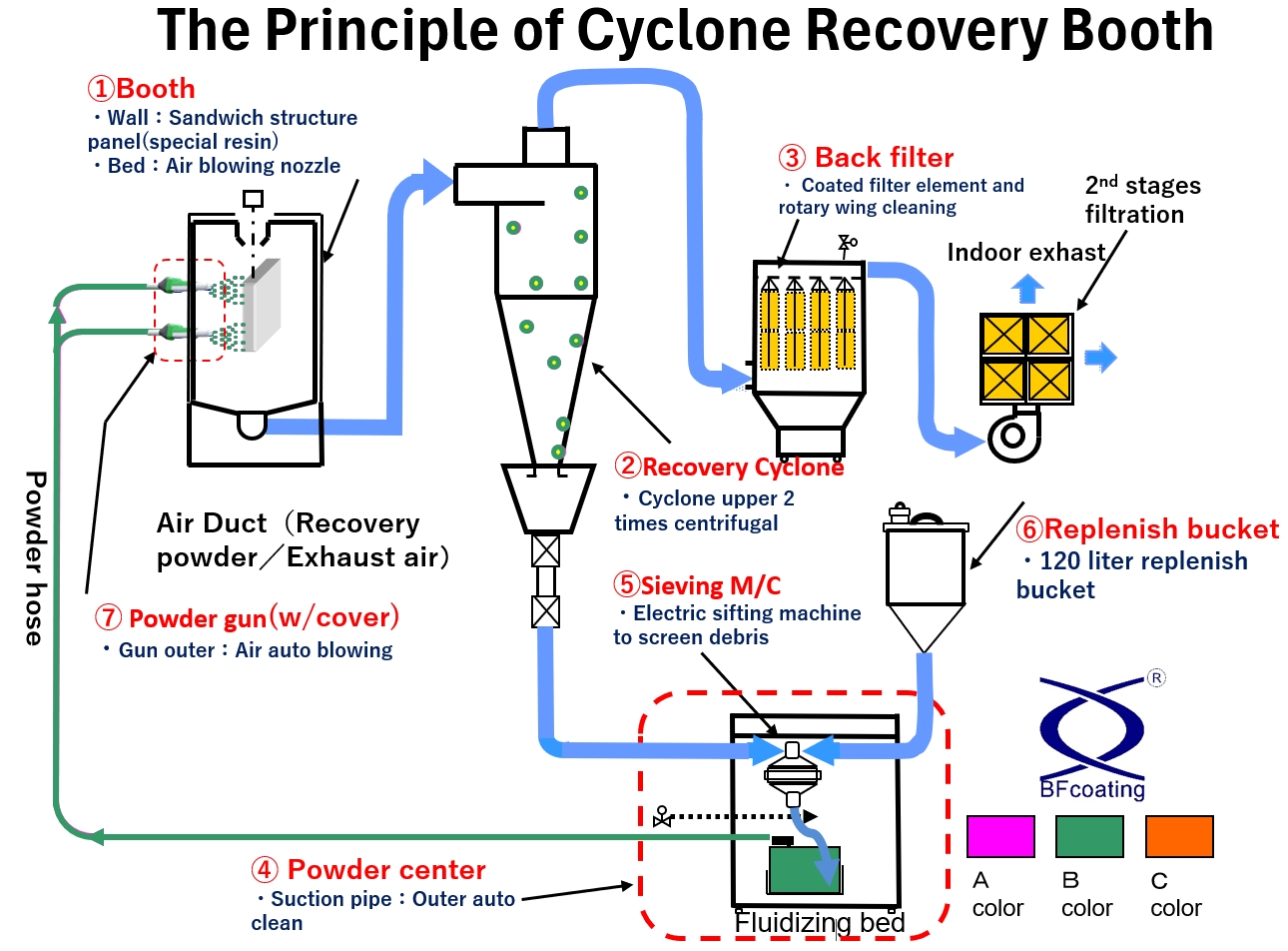

The Principle of Cyclone Recovery Booth

The Principle of Cyclone Recovery Booth

Powder Recovery Unit

Powder Recovery Unit

| Description | Single stage filter | 2nd stage filter | Multi-cyclone, 1st stage recovery unit | Large-cyclone, 1st stage recovery unit |

| Model | FU (Filter Unit) | BFU (Back Filter Unit) | MCU (Multi Cyclone) | CRU (Cyclone Recovery) |

|  |  |  | |

| Material | A3 steel panel, coated filter | A3 steel panel, Optional stainless steel | ||

| Specification | 6 sets-12 、9sets-18、 12sets-24 | 6sets-12、9sets-18、 12sets-24,16sets-32 | 6 tubes、9 tubes、12 tubes、16 tubes | Diameter 800, 1100, 1300,1400mm |

| Air volume m3/Hr | 8~10,000, 12~15,000, 16~20,000 | 8~10,000,11~14,000, 15~20,000, 24~28,000 | 8~10,000,11~12,000, 12~16,000,12~16,000 | 8~9,000,10~13,000, 18~22,000, 22~26,000 |

| Use occation | No color change, or less color | As 2nd recovery for cyclone | Need color change, but less plant height | Frequent color change |

*The height of one filter core is 660mm, and the upper and lower two filter cores form a set, with a height of 1300mm. 6-12: 6 sets of 12 filter cartridges. Tubes = number of multi-cyclone tubes. 800=diameter mm

Powder Supply Unit

Powder Supply Unit

| Model | PF Powder feeder | PFC Powder feeding center | PT Powder tank (add new powder) |

|  |  | |

| Tank Material | Stainless | A3 panel | A3 panel |

| Tank capacity (liter) | 150 | 120 | 250 |

| Vibration sieve | 1 PC | 1 PC, Optional 1 | |

| Color change cleaning | Auto clean tube | ||

| HMI | No. | HMI | |

| Gun quantity available | Max. 20 holes for powder suction unit | Max. 40 holes for powder suction unit | |

| Use occasion | No color change, or less color | Frequent color change |

*Gun quantity should be decided in the order sheet.

Classification of Powder Coating Reciprocator

Classification of Powder Coating Reciprocator

| Description | Oscillator | Reciprocator | 2 D Tracking Oscillator | Constant Speed Reciprocator |

|  |

|  | |

| Model | OSL | VR | OSL-T | VRF |

| Material | A3 panel | A3 panel | A3 panel | A3 panel |

| Stroke mm | 250~450 | Max. 1800/2200 | up/down 500, back & forth 500 | 1000, 1500, 2000, 2500 |

| Speed | 9~30 cycles/min. | ~45 m/min. | 9~40cycles/min. | ~60m/min. |

| Speed adjust | Inverter | Inverter | Inverter | Inverter |

| Base | Manual back & forth | Manual back & forth | Auto back & forth | Manual back & forth |

| Use occasion | No color change or less color | Need color change, but less plant height | Frequent color change | up/middle/low thickness difference 15µ request |