The Advantage of Plastic Powder Spray Booth

No.

LCB-P

Intro.

In powder electrostatic coating, the electrostatic needle of the powder gun is negatively charged, and the object to be coated is positively charged. The powder is polarized by the negative charge of the electrode needle, and the negatively charged powder

High-speed color change can be achieved within 10 minutes New powder color change system

Advantages of Plastic Booth in quick color changing

Advantages of Plastic Booth in quick color changing

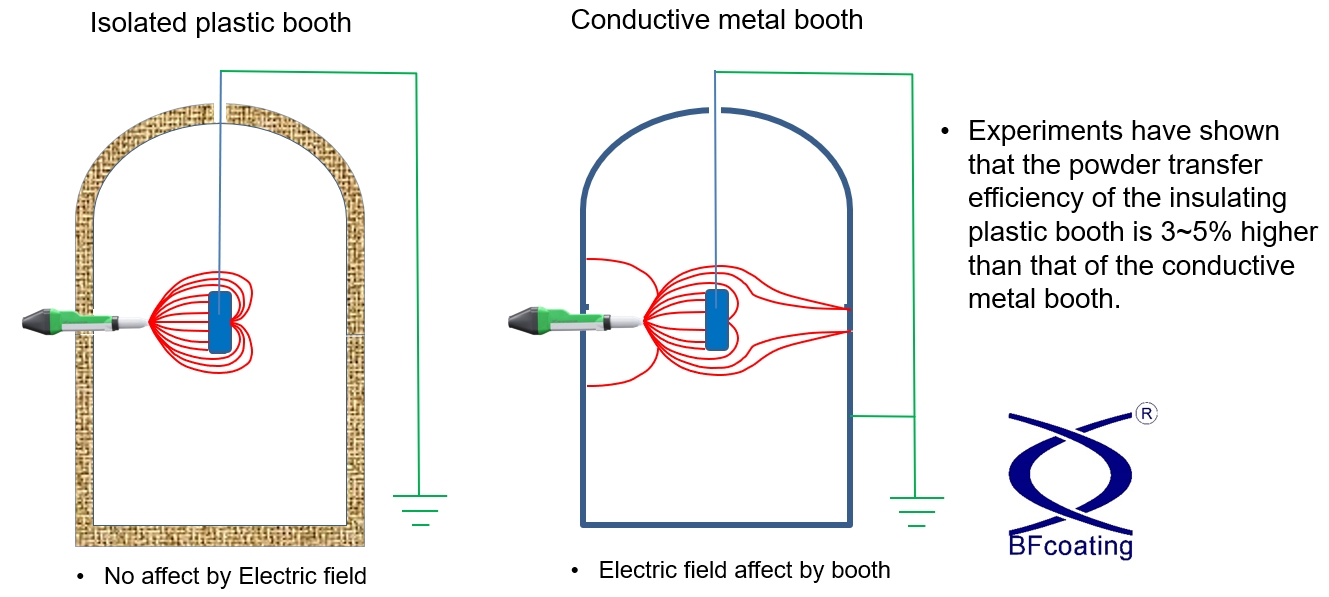

High coating efficiency

High coating efficiency

Because the plastic insulation board is used, the charged flying powder repels the wall panels of the same polarity, and attracts the coated objects of different polarities.

Quick color change

Quick color change

Because the plastic insulation board is used, the charged flying powder is repelled by the wall panel of the same polarity, and the powder sticks to the wall panel and needs to be removed less.

Less powder accumulation at the bottom and high yield

Less powder accumulation at the bottom and high yield

There is a powder blowing jet at the bottom of the spray booth, which continuously moves the powder to the air suction port to prevent powder from accumulating at the bottom and causing inconsistent coating quality between re-used and fresh powder.

Good strength and high safety

Good strength and high safety

Made of plastic sandwich board wall thickness of 120mm, it does not change shape and is strong and durable.

Powder recovery efficiency can be as high as 98%

Powder recovery efficiency can be as high as 98%

Use advanced large cyclone technology and unique secondary separation design

Optional spray gun cleaning device

Optional spray gun cleaning device

Special air nozzle design, automatic gun body external cleaning