•LE200/300 is used in various field

Character

Character

• Easy and quick installation

Simple structure, easy to install and test

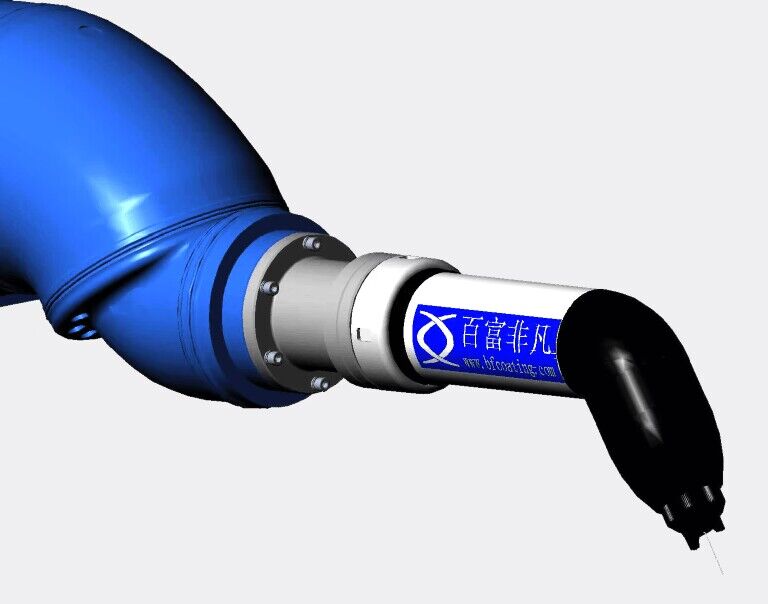

Suitable for robots with low wrist loads

• High transfer efficiency

Dynamic design of atomized particle size, flow velocity and air resistance

Various air caps have different choices corresponding to the spraying distance and dead-end penetration.

• Improved paint film quality

Small atomized particles, high particle uniformity, and good touch

The film thickness uniformity distribution of air + electrostatic atomization is relatively uniform

• Tungsten steel paint valve switch gun with long service life

On/Off once every second with a long life.

• Easy maintenance and management

The pipelines are on the robot's 2nd arms, easy to disassemble and maintain

Low parts costs and low operating costs

•Comply with environmental protection regulations

Build new coating lines or upgrade old coating lines are comply with new environmental regulations

Specification

Specification

Model | LE200SB-H/N | LE300SB-H/N |

Structure and character | For hollow wrist robot / Non-hollow wrist robot | |

Application paint | Solvent base paint | Solvent base paint |

High voltage type | Internal HV | Internal HV |

High voltage | 85kv x 100µA | 85kv x 100µA |

Integrated valve | Paint on/off and dumping | Paint on/off |

Min. starting air pressure | 0.4 Mpa | 0.4 Mpa |

Air consumption(Pattern) | Φ 8Ⅹ6 600L/min.(ANR) | Φ 8Ⅹ6 600L/min.(ANR) |

(Pressure 0.45Mpa)Atomization | Φ 8Ⅹ6 600L/min.(ANR) | Φ 8Ⅹ6 600L/min.(ANR) |

Flow rate( Pressure 0.7Mpa) | 500mL/min | 500mL/min |

Double layer Teflon paint hose | 6 x 8 | 6 x 8 |

Paint flow rate setting (Pneumatic type) | MR30 remote control paint valve | MR30 remote control paint valve |

Paint flow rate setting (Gear pump type) | #10, 30 type | #10, 30 type |

Pattern based on air cap | 100~350mm | 100~350mm |

External size | 394mmxØ96 | 394mmxØ96 |

Weight( excl. cable, soft hose and nozzle) | Approx.3000g | Approx.3000g |

High voltage cascade | CC851B | |

Electrical box (PC board, small box, hardware) | IPS930E | |

Electrostatic controller | IPS930C/HMI | |

* H= With Hollow wrist robot flange , N= With NON-hollow wrist robot flange

LE300N (GP25-12)

LE300N (GP25-12)

LE300H (MPX2600)