The tribomatic spraying method uses powder to pass through a friction tube at high speed to cause the powder to rub and become charged. This type of coating equipment consists of a p

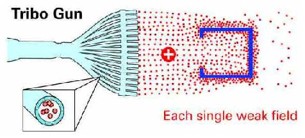

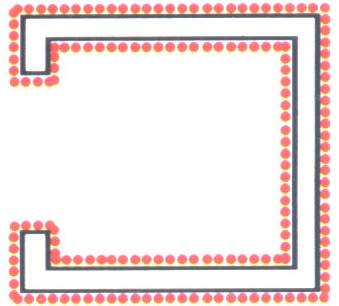

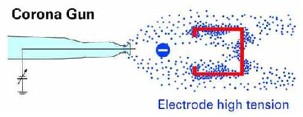

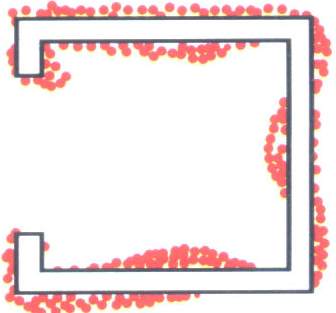

Typical C beam application: Comparison of tribo spray guns and high voltage corona spray guns

| Principle comparison | Performance | Analysis of effect |

|  | Much over spray, much recycling powder and waste powder, poor coverage,Touch up is necessary, the orange peel is more serious, the film thickness is uneven, and the paint is wasted. |

|  | High transfer efficiency, good full coverage, fully automatic. thickness of flat surface coating is particularly smooth, saving 20~40% of powder |

Advantage of Tribo spray gun:

| Features | Description of advantage | |

| 1 | Faraday effect | The powder easily enters the deep recess of the workpiece, and does not has over fatty in edge and dead ends. |

| 2 | The possibility of automation | The powder enter into deep holes, corners, and narrow grooves easily, and can be applied to no touch up powder coating. |

| 3 | Uniform distribution of coating film | No faraday effect, no repulsion, can be used for ultra-thick coating, and can reach 400 microns in one-time spraying. Some powders can achieve film thickness less than 30 microns. |

| 4 | Orange peel | Weak high pressure, uniform powder cloud, uniform multi-finger spray pattern. The same powder which use conventional electrostatic spray will appear orange peel , but Tribo spray won't. |

| 5 | Electrostatic field | Each charged powder generate a weak electric field, air blow the powder to adhere on specified point, the film thickness of the inside and outside of the recess and the corner is the same, which can save 20-40% of the powder. |

| 6 | Multi coating | Because there is no repulsion phenomenon, under the requirement of heavy anti-corrosion, it can do multi-layer spraying without pinhole and crater phenomenon. |

| 7 | Multiple production capacity in the same production area | The art of weak electrostatic field and powder flow rate control enables flat workpiece to be stacked spray in direction of the conveyor. The production in same area can be multiple. |

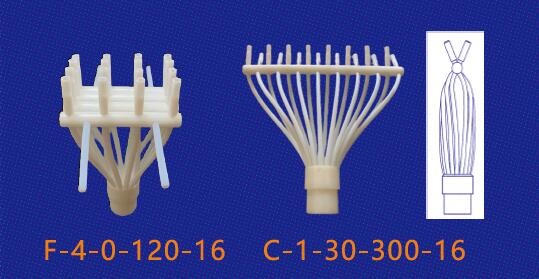

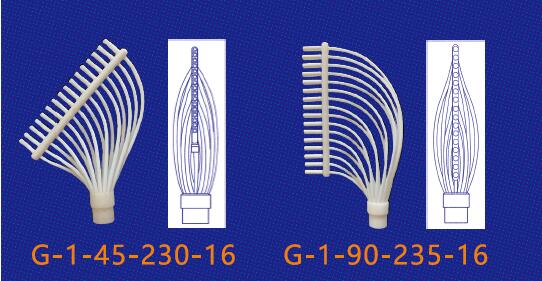

| 8 | An all-round spray gun | The spray gun can equip various nozzle in according to requirements of workpiece for all-round spraying application. |

| 9 | Relationship between powder flow rate and recycling | The powder flow rate of tribo coating is less than conventional corona coating. Although the flow rate is small but transfer efficiency is high, the yield is not affected. The load of the recovery system can be reduced, and the energy consumption and maintenance cost are small. |

| 10 | Powder flow rate and transfer efficiency | In some cases, the efficiency of tribo coating can exceed 80%. For some coating cases that require high quality without recycling paint, the tribo coating is the most economical choice for powder coating. |

Baifu Automatic Tribo Frictional charging powder spray equipment

| Specification of Tribo gun | |

| |

| Model | T-1a |

| Gun weight | 1000 g |

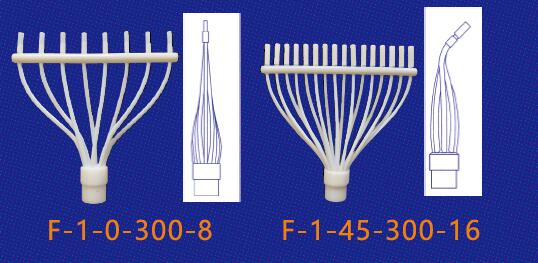

| Standard nozzle | 260mm,16claw |

| Compressed air | 5~7kg/cm2 |

| Trasnfer efficiecy | 60-90% |

| Powder output | 250 g |

| Powder hose | 10Фx 5m * |

*Other lengths are quoted separately

| Specification of controller | |

| |

| Model | BPS320 |

| Weight | 3000 g |

| Power source | 220V ,50/60Hz |

| Charging display | Digital display |

| Compressed air | 5~7kg/cm2 |

| Main cabinet | Optional |

Advantage of T-1a :

█ Best electrification effect, large powder output

█ Less consumable parts

█ Uniform atomization

█ Variety of nozzles can be selected

█ Interchangeable with old type spray guns

Advantage BPS320 :

█ Simple operation

█ Compact in rack design,easy installation

█ Charging current with digital display

█ Comfortable 3 gauges design

█ High reliable

Success Case Video

Success Case Video