2021.08.13

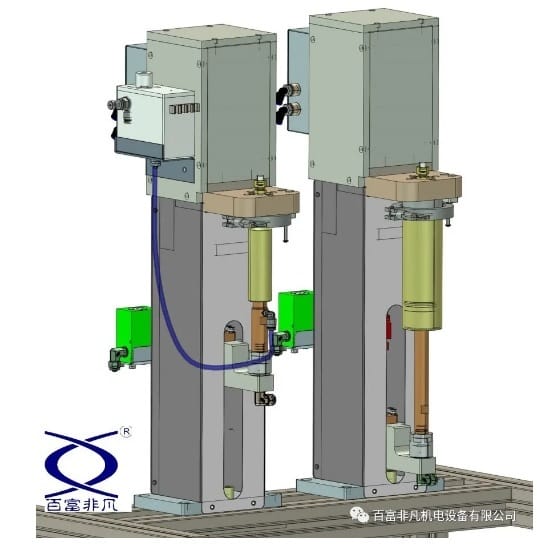

S2K/3K Syringe pump volume mix

Advantage:

- The syringe pump can always provide stable paint supply that not affected by change of temperature, thixotropy , viscosity , paint blockage, UV paint clogging, silver powder paint clogging, non-viscous water, etc.

- Set the ratio of main agent and hardener of different products and the required amount of paint output by computer.

- Low discharge rate,less than 20cc per minute can maintain the stability of paint output.

- The accuracy of proportion and paint flow rate can reach ±1% or higher.

Working principle:

Syringe pump adopts a piston pump driven by a pulse servo motor, and a volumetric computer PLC pulse calculus for accurate paint supply.

The difference between syringe pump and traditional metering method:

Most of the traditional paint ratio and measurement methods are: gear flow meter type, Coriolis quality flow meter, stroke metering type, ultrasonic cartridge type and so on. The gear type has problem of UV, silver powder clogging, and internal leakage. Coriolis is expensive. The ultrasonic cartridge type needs to be corrected for various fluids. At the same time, these two flow meters need to be installed in an environment without vibration or shaking.

The selection of various paints viscosity range and flow meters:

The precision and paint flow rate comparison of each paint flow meter: