SS2K Syringe VoluMix 2k

No.

SS2K

Intro.

1. The metering pump is not affected by temperature changes, thixotropic changes, viscosity variations, paint line blockages, UV pump seized up, silver particle pump jammed, or low-viscosity fluids like water, enabling consistent and stable paint supply at all times.

2. Computer-controlled settings are used to adjust the mixing ratio of main agent and catalyst agent, as well as the required paint output (in cc) for different products.

3. A low discharge rate (less than 20cc per minute) can maintain stable paint output.

4. The mixing ratio precision and paint output precision can reach up to ±1% or higher.

2. Computer-controlled settings are used to adjust the mixing ratio of main agent and catalyst agent, as well as the required paint output (in cc) for different products.

3. A low discharge rate (less than 20cc per minute) can maintain stable paint output.

4. The mixing ratio precision and paint output precision can reach up to ±1% or higher.

Advantages

Advantages

- Metering pumps are not affected by temperature changes, solubility changes, viscosity variations, paint line blockages, UV pump seized, silver particle pump jammed, or water with less viscosity, ensuring stable paint supply at all times.

- Computer settings are used to adjust the ratio of main agent to hardener and the required paint output in cc for different products.

- Even at low output rates (less than 20cc per minute), stable paint delivery can be maintained.

- The mixing accuracy and paint output precision can reach as high as ±1% or better.

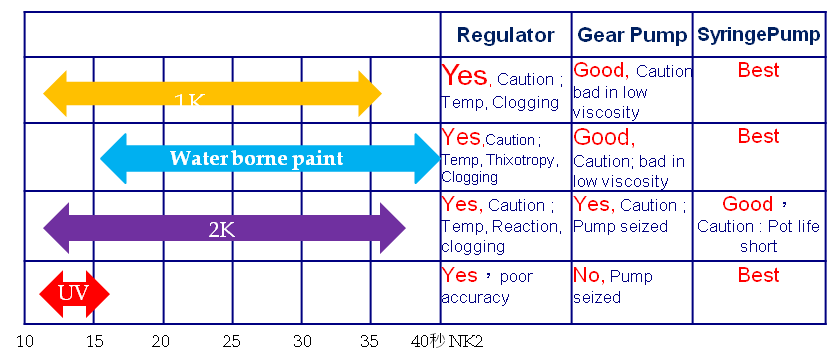

Understand the differences between currently commonly used paint pressure regulators, gear pumps, and syringe metering pumps

Understand the differences between currently commonly used paint pressure regulators, gear pumps, and syringe metering pumps

| Diaphragm Pressure Balance Adjustment Metering | Volumetric Gear Metering | Volumetric Syringe Metering | |

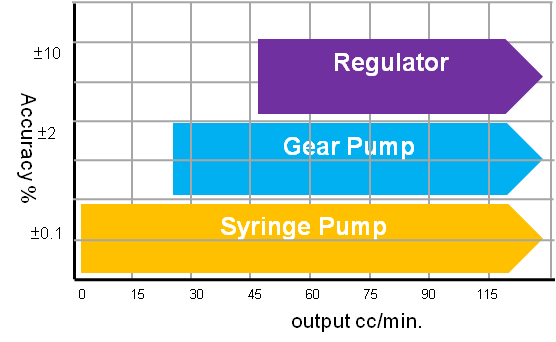

| Accuracy Level | ±10% | ±3% | ±1% |

| (Variability Error with Backlash Internal Leakage) | (no inner leakage) | ||

| Illustration |  |  |  |

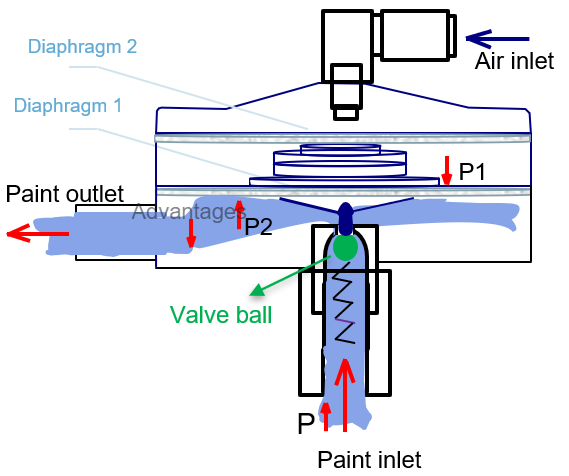

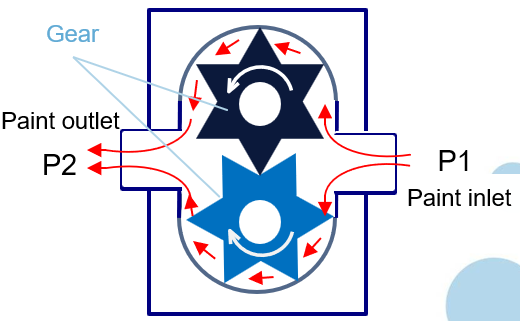

| Working Principle | P1 (air pressure or spring force) pushes the valve ball open, allowing paint to enter the chamber P2 (paint pressure) reduces the valve ball gap, decreasing paint flow and subsequently lowering P2 pressure The paint output is determined by the balance between three forces: the inlet paint pressure, the outlet pressure P2 (chamber pressure), and the air pressure (or spring force) on the P1 diaphragm. | Variable frequency motors and servo motors drive gears to rotate The paint in the space between gear tooth tips and the pump body is carried by gear rotation to the pump outlet and discharged outside the pump body The rotation speed represents the volume of paint discharged between gears, which is converted digitally for paint output data management | Precision Servo Linear Control Measurement |

Understanding the representation through charts makes it easier for you to choose paint quantity control options.

Understanding the representation through charts makes it easier for you to choose paint quantity control options.

Specification of SS2K Syringe Metering Pump type 2 components auto Dosing & Mixing machine

Specification of SS2K Syringe Metering Pump type 2 components auto Dosing & Mixing machine

| Proportioning Dosing Machine Model | SS2K |

| Proportioning Metering Method | Servo Injection Metering |

| Flow Rate cc/min. | 40 to700 |

| Paint Output Stability | ±1% |

| Maximum Working Pressure of Paint | Low Pressure Spraying 1MPa |

| Maximum Working Pressure of Air | 0.7MPa |

| Maximum Working Air Pressure | 0.45 to 0.7MPa |

| Air Source | 0.6 to 0.7MPa |

| Air Filter Inlet Size | 3/8 npt(f) |

| Air Filter for Control (Equipped with the Machine) | Minimum 5μm, Clean/Dry |

| Air Filter for Spraying Atomization (Supplied by Integrator) | Minimum 30μm, Clean/Dry |

| Suitable Paints | Single-component, Two-component; Solvent-based and Water-based Paints; Polyurethane; Epoxy Resin; Acid-cured Varnish; Moisture-sensitive Isocyanate |

| Paint Viscosity Adaptation | 20~1500cps |

| Paint Filter Device (Supplied by User) | 60, 80, or 100 Mesh |

| Maximum Proportioning Range (Proportioning Accuracy Varies Slightly with Viscosity and Proportioning Ratio) | 100:01:00 |

| Paint Outlet Connector | 1/4 npt(m) |

| Allowable Operating Temperature | 10 to 45℃ |

| Absolute Flow Control Accuracy | 0.15cc (Micro-control Accuracy can reach 0.1cc) |

| Maximum Flow Repeat Control Accuracy | ±1cc/min |

| Components in Contact with Paint | SUS316, SUS304, Steel, PTFE, Perfluoroelastomer, UPE, Ceramic |

| Optional Metering Pumps | 70, 40, 10 |

| Equipment Dimensions (LWH) mm | 600x600x1750 |

| Stand-alone Weight | Approximately 80 kg |

| Working Power Supply | 200/240VAC, 50/60HZ |

| Installed Power | 1.2kW |

SS2K

*Water-Based Electrostatic Insulating Coating SW3K - Please Inquire Individually